|

|

Medco and predecessors.  Medco circa 1940. George King, a well-known timber man of Eureka, returned overland from Portland last week after an absence of several weeks. He has just closed a timber deal in Portland whereby, for the sum of $60,000, he transferred to Wm. E. Wheeler of Pennsylvania 4,000 acres of pine and fir in Jackson County, Oregon. The purchasers intend commencing the manufacture of lumber in the near future. A large lumber plant will be erected either at Medford, Gold Ray or on the Rogue River in Oregon, but at present no decision has been made in the matter of a site for a mill. "Cream of County News," Blue Lake Advocate, Blue Lake, California, August 29, 1908, page 7 A. L. See, a timberman of Medford, who is staying at the Manx, says that there are nearly 100,000 acres of virgin timber land in California and Oregon, and that when these are opened up the Northwest will be the timber center of the world for many years to come. Mr. See said: "Few realize the amount of timber there is in the Rogue River Valley. From surveys just made an estimate may be formed of the amount of timber there when it is said that if four railroads, operating four trains a day each with 100 cars it would require 100 years to haul the timber now standing in the valley. As a matter of fact this section is already taken up by a big company, and several railroad companies are bidding for the hauling privileges and are planning to put in roads running from the Rogue River Valley to Coos Bay and Bandon. With the opening of the Panama Canal the timber men of California and Oregon will be able to compete with the world." "Hotel News," San Francisco Call, March 4, 1913, page 6 BIG TIMBER DEAL MADE

MEDFORD,

Or., March

16.--(Special.)--The first step in an extensive lumber deal was

consummated today when the Hart tract of 6000 acres, near Butte Falls,

was sold to Owen Brothers, of Eau Claire, Wis., and Portland, Or. The

deal has been pending for some time, and it is probable that the

Harkness tract of about the same area will be transferred in the near

future. Although no price for the Hart tract was made public, it is

estimated at $180,000.TWO TRACTS OF 6000 ACRES EACH NEAR MEDFORD INVOLVED. Owen Firm of Wisconsin and Portland Principals--Railway Extension and New Mill Expected. The deal will involve the extension of the Pacific & Eastern Railroad seven miles and the probable construction of a mill and box factory in Medford at a cost of $100,000. P. W. Murphy probably will be manager of the Butte Falls plant and will move to that city soon with his family. Frank Owen, of Portland, has been in Medford for several months. The Hart tract has been carefully cruised and every phase of the matter investigated. If the entire deal goes through it will mean the development of the timber resources near Medford, the extension of the Pacific & Eastern, and the pouring of thousands of dollars into Medford for several years. Morning Oregonian, Portland, March 17, 1914, page 5

RECEIVER'S

SALE PACIFIC-EASTERN HELD TOMORROW

Much interest is being manifested in the

sale of the Pacific & Eastern Railroad at auction at 2 o'clock

tomorrow afternoon at the depot under orders from the federal court of

this district, by Robert F. Maguire of Portland, who is expected to

arrive in the city today.According to rumors there will be several bidders for the property. The most prominent probable bidder is M. D. Olds of Sheboygan, Mich., who arrived in Medford on Sunday and is stopping at the Hotel Medford. Mr. Olds and his agents have spent much time here during the past year buying up timber along the route of the Pacific & Eastern. His main representative stated this noon that neither he nor Mr. Olds had anything to say about the big sale Tuesday, which means so much to the future welfare and development of Medford and the towns along the P.&E. railroad. Medford Mail Tribune, August 23, 1920, page 6 SIX BILLION FEET OF PINE AND FIR

TAPPED BY P.&E.

Now that the Pacific & Eastern Railroad has been sold, all the

Medford and Jackson County public is wondering what the new owner's

plans are in connection with the operation of the road, and when he

will start it. But M. D. Olds won't talk.

However, the fact he has for the past year or more been busy buying up timber holdings and leases in the territory contiguous to the road and the fact that at least one new large mill is in contemplation for Medford leads to the general belief that he will operate the road partly in connection with this contemplated project. Another patent fact to the well informed is that there are six billion feet of the best timber in Oregon, 60 percent fir and 40 percent pine, in the country east of Medford, mostly in the Butte Falls section, which would be tapped by the operation of the Pacific & Eastern. While there have been and are many rumors in connection with Mr. Olds and his ownership of the road, some of which, if true, would have a stupendous bearing on the future welfare and development of Medford and the valley, nothing will be known until the Michigan lumber man's plans are perfected. The fact that Mr. Olds refuses to rush into print is taken by many as a good sign, showing that he is not the type of hot air promoter which has led the people of Medford to entertain false hopes so often in the past. As it is now, the people of Medford, Eagle Point, Butte Falls and the general residents along the P.&E. line are happy that Mr. Olds has bought the road and the strong probability that he will put it in operation within the next year. But about the sale yesterday: Notwithstanding the rumors that there would be several probable bidders and the fact that until a few hours before the auction the Miller Grier Construction Company of Portland contemplated bidding and had their first payment check of $15,000 deposited, the Pacific & Eastern went under the hammer to M. D. Olds, who was the only bidder, for $196,600, of which $15,000 was to be paid at once and the balance in 60 days. The sale was conducted by attorney Robert F. Maguire of Portland, special master for the United States court in conducting this transaction before a crowd of about 100, and Mr. Olds' bid was just the exact amount set by the court as the minimum price which would be accepted at the sale. The Pacific & Eastern had an estimated scrap value of $438,000, according to W. E. Turner, its receiver, who is vice president of the Spokane, Portland & Seattle Railroad Co. and System Lines, who after the sale before departing for Portland last night with C. H. Hart, attorney for the receiver, said that the Hill railroad interests favored the sale at auction at the minimum price set by the court, rather than to see the railroad torn up and scrapped. The rolling stock of the P.&E. went with the sale, consisting principally of two engines, two passenger cars, one box car and six flat cars. The road also had been using for years six S.P.&S. railroad cars, which will probably be taken over by the new owner. The Miller Grier Construction Company's failing to enter a bid at the sale yesterday is a mystery, as during the forenoon G. M. McDowell, its secretary and treasurer, while in the Mail Tribune office with receiver Turner stated that it would try and purchase the road, and that if it was successful at the sale the company would see that it was operated in the interests of development of the great timber territory east of Medford. The Pacific & Eastern was built in 1909-1910 by John F. Stevens, the famous engineer, now in Siberia, and was then intended to complete the link of the Hill system between Bend and California. Medford Mai Tribune, August 25, 1920, page 5 START WORK ON BROWNLEE MILL; RUSH

BUILDING

Head Men on Ground for Erection of Plant--Machinery Shipped--Six Months Before Operation--To Employ 500--Will Build Roads into Timber--Develop Timber Holdings

The

commencement of work by the Brownlee Lumber Co. on their big lumber

mill on their 32-acre site just north of Medford will be received with

great enthusiasm, not only by the people of Medford, but of all

southern Oregon, as it means a big thing for the city and valley,

bringing a payroll of more than 500 people when the mill is in

operation and adds another unit to what promises to be one of the

biggest industries of the valley.

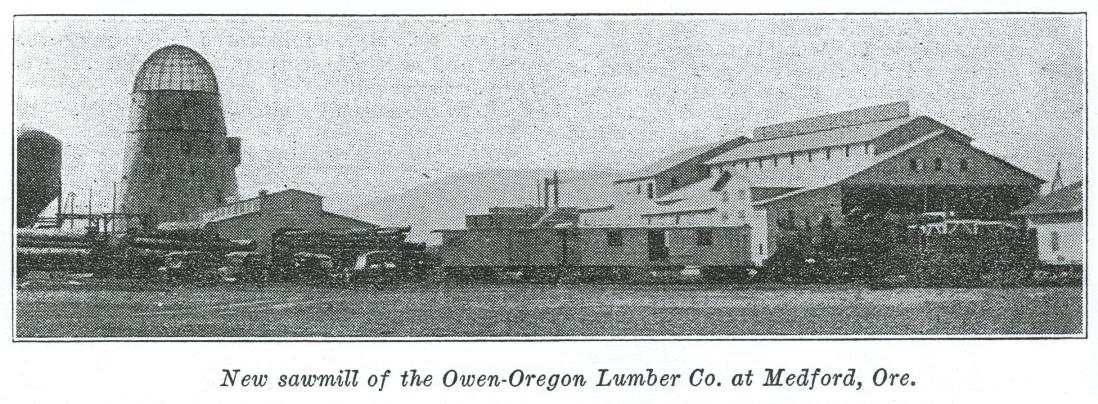

MAIN PLANT OWEN-OREGON LBR. CO.The mill site is just north of the Pacific & Eastern track and on the Southern Pacific, and Mr. Brownlee, Sr. says that if the P.&E. is not in operation when their mill is erected when their mill is erected they have arrangements made to secure plenty of logs to be shipped on the Southern Pacific. A temporary office has been built for the mill site. Measurements are being made for the different buildings, and work will be pushed along as rapidly as possible. It will take six or eight months to complete all the buildings and install the machinery. The plant will have a capacity of 125,000 to 150,000 every eight hours and the mill will be run on double shift when in full operation. J. N. Brownlee and his sons, J. G. and R. O., are the sole owners of the Brownlee Lumber Company, all of whom are here and will be actively engaged in the mill. Their logging superintendent, cruiser and head mechanic are also here directing preparatory work. This company has been conducting extensive operations near Shubuta, Miss. but have sawed out all their holdings and are tearing down their mill and logging road there to move to Medford. Part of the new machinery to be put in the mill here has already been shipped. The Brownlee company has been purchasing timber lands around Medford for more than a year and now have between three and four million feet and are purchasing more. They will build eight or ten miles of road from the P.&E. tracks to connect with their timber holdings. Medford Mail Tribune, September 9, 1920, page 6 BROWNLEE PLANT TO BE COMPLETED

SOON

J. N. Brownlee, who returned recently from a trip to the East and

Southern states, says conditions for the lumber mills look brighter and

that the recent reduction on freight rates will also be a big help to

the western mills. The Brownlee Lumber Company's mill in north Medford

is progressing nicely and will be completed this summer. Several

carloads of machinery have been put in place and two more carloads were

received this week.

Medford Mail Tribune,

April 5, 1921, page 5

"Lumber activities and irrigation are the two big things which are interesting Medford people just now," reports S. S. Smith, newspaper man of Medford and member of the Republican state executive committee for Jackson County. "The Pacific & Eastern Railroad, which runs from Medford to Butte Falls, is being reconstructed and is to be extended 12 miles into the Four-bit timber which Mr. Olds, owner of the road and the timber, bought some time ago. The Brownlee Lumber Company has about completed the mill which it has been erecting for nearly a year and the mill is waiting on the extension of the railroad, for the Brownlee plant will cut for Mr. Olds and Brownlee. The plant will give employment to several hundred men. The timber to be tapped is what is said to be the largest body of pine in the state--timber in which an ax has never been set." "Medford People Prominent in Portland News," Medford Mail Tribune, January 19, 1922, page 3 NEW OIL-BURNING ENGINE BOUGHT BY

P.&E. RAILROAD

Medford Mail Tribune,

March 31, 1922, page 6

The Pacific

and Eastern Railway

has recently received from the Porter Bros. shops in Pittsburgh, Penn.,

a new, prairie type, 62-ton, oil-burning locomotive. The new engine was

shipped from Pittsburgh via San Francisco and arrived here via the

Southern Pacific several days ago.

A test run was made with the new locomotive about the first of the week and the functioning was above the highest expectations of the officials of the road, the engine having drawn 25 cars from this city to Eagle Point and passing over the grades in the steepest places without difficulty. It is understood that a number of men have been employed all winter getting the road in condition for operation this spring and that the work is nearing completion. It is expected that the transportation of logs from the Butte Falls timber district will soon begin and that the mills will start operation in the near future. The Medford sheet metal works has constructed a galvanized iron tank of 7000 gallons capacity for the storage of the fuel oil to be used in the locomotive. BROWNLEE MILL READY TO OPERATE

Largest Lumber Manufacturing Plant in Southern Oregon Ready to Start As Soon As P.&E. Brings Down the Logs-- Expect to Put Out 125,000 Board Feet a Day.

The Brownlee Lumber mill which has been under construction for the past

year is now complete and ready for operation, and will begin cutting

logs as soon as the Pacific & Eastern Railroad

supplies them in

sufficient quantities from the Butte Falls timber belt.

The mill has an estimated capacity of 125,000 board feet per day and it is expected that when the mill is put into operation this estimate will be exceeded in output. A planing mill to be used in connection with the sawmill and sufficient in size and capacity to surface all of the output of the sawmill is now nearing completion. A millpond, from 5 to 10 feet in depth and more than 5 acres in area, has been constructed and is now full of water ready to receive logs from the railroad. The Brownlee mill, which has recently been completed and which is now ready to cut lumber at any time the P.&E. railroad can deliver it, is the largest, most modern and complete lumber manufacturing establishment in Southern Oregon. The lumber will enter the mill from the 5-acre pond in the form of logs and will be transferred to the two carriages which are drawn past the large bandsaw and the circular saw at breathtaking speed by the long steam cylinder, termed "shotgun" in sawmill parlance. Handle Giant Logs

There are two of these carriages, the largest of which will handle logs

up to and including 7 feet in diameter and which passes a bandsaw with

a blade 12 or 14 inches in width. The Cunningham band mill

which cuts

the boards from the log carried on the large carriage is driven by a

two-hundred-horsepower steam engine. The carriage has been arranged so

that logs of considerable length may be cut, but it is not anticipated

by the management that any lumber will be cut in excess of 20 feet in

length.The circular saw on the other side of the mill is provided with a similar carriage and has been installed for the cutting of logs of small diameter, being capable of cutting logs two feet or less in diameter. Both carriages have steam-operated setwork. That is, a number of levers and ratchets operating the rack and pinion arrangement on the carriage for the purpose of advancing the log into a plane with the saw the distance of the desired thickness of the board to be cut do not have to be operated by hand but are operated by one man who holds a control lever in his hand and who sets the log the desired thickness of the next cut by a mere movement of the lever. Nine Circular Saws Operate

After the lumber has been cut from the log it will be ripped to the

desired width and will be passed on to the trimmer where nine circular

saws cut it into the desired lengths. Four circular saws are provided

for the cutting of the bark into four-foot lengths for slab wood. The

lumber is to be fed to these latter saws by a system of endless chains

as is customary in sawmills. The slab wood will drop into a large bin

from which it will be taken for fuel purposes and the lumber will be

carried on a long trestle across the mill pond to the east side where

it will reach the sorting table. This transportation is effected by

means of endless chains and cables running on top of the trestle. All

of the machinery in the mill with the exception of the band mill is

operated by a second large steam engine of about 500 horsepower.Big Battery Boilers

A battery of four large sawdust-burning boilers supplies steam to the

engines, "niggers" which are used for shifting and rolling the logs

into their places in the mill, and "shotguns."A complete shop which is now in a temporary building is also an adjunct to the mill and comprises a large lathe, a drill press and other metalworking machinery. Cut 87,500,000 Feet

It is understood that the mill will cut 87,500,000 feet of timber to be

logged by the Millard D. Olds interests. owners of the P.&E.

railroad and of large timber interests in this vicinity. The referred

to timber is situated in the Butte Falls district and requires the

extension of the P.&E. railroad for a distance of

11½ miles above

Butte Falls. It is understood that several miles of the extension have

been completed up to the present time, although the management

of the

railroad will give no definite information as to the progress which has

been made during the past year. The timber to be cut is in the Four-Bit

tract of the Crater National Forest and was purchased a year ago by the

Olds interests. The conditions stipulated by the government call for

the beginning of cutting operations on or before June 1st, 1923. So,

despite the silence of the management of the road the public may be

assured that operations will begin within the next year.Medford Mail Tribune,

June 9, 1922, page 24

PUBLIC INSPECTION BROWNLEE MILL

TOMLIN FACTORY

Tomorrow's

program of "Prosperity Week" consists of a recognition of the

industrial and irrigation development that has taken place in the Rogue

River Valley within the last few years.

Between the hours of ten and twelve tomorrow morning, the general public is invited to inspect the Tomlin Box Co., the big new Brownlee Lumber Mill and the dumping of logs from the cars of the Pacific & Eastern railway into the mill pond of the Brownlee mill. The Rogue River Canning Co., and other industrial plants will be open for inspection. The Brownlee mill and the operation of the Pacific & Eastern are the two big factors that will bring greater prosperity to the valley than is now being enjoyed. At two-thirty in the afternoon the D.O.K.K. band will start the ceremony at the city park at which the irrigation development, especially the construction of the Medford Irrigation District system, will be given recognition. The ceremony is in charge of a committee of the Medford Chamber of Commerce, of which Benj. C. Sheldon is chairman. In the evening the Medford Post of the American Legion will stage a busy night in Jacksonville in 1848. [No white people lived in the Rogue Valley in 1848.] No human being, unless he lived in Jacksonville at that time, can visualize what such a night really included, and a correct reproduction in every detail is promised. Medford Mail Tribune,

June 14, 1922, page 6

BROWNLEE-OLDS MILL TO MAKE 1ST

RUN MONDAY

The Brownlee-Olds Lumber Co. will make the first run of the big new

mill in North Medford next Monday and hope after a few days of

adjusting machinery and doing other things necessary to starting a

plant, to be running steady.

This will be welcome news, as it means the employment of a large number of men, a splendid payroll and the opening of the lumber industry in this community on a large scale. A logging camp was established near Butte Falls the first of the week and the number of men will be increased as the demand of the mill requires. The railroad has been rebuilt to Butte Falls, the new road graded several miles from there into the lumber district, fifteen new modern logging cars of 80,000-pound capacity, built in Oregon, were received this week, and with the twenty other logging cars and three engines, makes a splendid equipment for the logging road. The new whistle you hear of mornings, noons and nights is the mill whistle. They are also digging a large well to supply water for the mill and mill pond. Medford Mail Tribune,

June 14, 1922, page 6

Circular Saw Bites into First Log

at Brownlee's Lumber Mill

The teeth of the big circular saw at the Brownlee mill bit into the

first fir log Tuesday morning and the mill will now continue operation,

steadily increasing its output and crew daily for some time to come.

The management expects to saw between 60,000 and 70,000 feet of lumber a day, working one shift, within the next month and between 125,000 and 150,000 feet within another two or three months when the band mill will be started. Only one side of the mill is now in operation, the big band mill resting until the P.&E. railroad, which brings the logs from Butte Falls, gets its full equipment and is operating to capacity. The railroad has ordered 15 new logging cars from the Pacific Car Company in Portland, four of which have already arrived, and is having a number of flatcars rebuilt for logging purposes. The five-acre mill pond, with a capacity of 3,000,000 feet of lumber in logs, is about one-fifth full and the management counts on these logs to keep one side of the mill busy until the railroad is operating steadily. The railroad also furnishes logs for the sawmill of the Tomlin box factory, which is cutting a large quantity of lumber and turning out hundreds of thousands of boxes per annum. It has been more than two years since the beginning of construction of the Brownlee mill which has been practically complete for some time. A planing mill which is capable of handling and surfacing all of the lumber which the big saw can cut has also been constructed and both have been waiting for the operation of the railroad for several months. All day Monday was spent making final adjustments on the mill machinery which was finally put in satisfactory operating order yesterday. Medford citizens are glad to see the mill in operation at last and merchants and business men welcome the addition which it will make to the local payroll. Medford Mail Tribune,

August 9, 1922, page B5

BROWNLEE LUMBER GETS EQUIPMENT

FOR SPRING WORK

Two Clyde

skidders

were received this week by the Brownlee Lumber Company for use in their

timber operations in the Butte Falls district, and are being shipped to

that section. The skidders are the same type as used by the Weed Lumber

Company in their logging, are a highly complicated piece of machinery,

and some idea of their size can be gained from the fact that six

flatcars were used in transporting them from the East. They are used in

hauling logs with wire cables to the tracks, and take the place of the

old donkey engines.

A leader and steam shovel to be used in the work are en route from the East, and are expected to arrive this month. It is expected that the machinery will all be on hand and installed by February 1st and ready for operation at that time, though no definite date has been set. Medford Mail Tribune,

December 5, 1922, page 3

JAMES H. OWEN HERE TO INSPECT

LUMBER SITUATION

Mr. and Mrs. James H. Owen arrived in Medford the first of March after

a several months' visit in the East and expect to remain here for the

next two months.J. H. Owen, who resigned from the presidency of the California and Oregon Lumber Company at Brookings, Ore., and disposed of his interests in that concern last fall, is looking for a location to begin lumber manufacture again. He is looking over the situation here and states that he has made no definite decision as to the beginning of operations. A. R. Owen, representing the John S. Owen interests, of Owen, Wis., will arrive about May 1, to collaborate with J. H. Owen and give the situation a close inspection and fuller consideration. The John S. Owen interests own approximately 15,000 acres of timber in the Butte Falls district which is penetrated by the Brownlee-Olds Lumber Company railroad. A little over half the timber is yellow and sugar pine while the remainder is Douglas fir. The John S. Owen interests also own the John S. Owen Lumber Company at Owen, Wis., near Eau Claire, and the Rust-Owen Lumber Company at Drummond, Wis. In regard to the local situation Mr. Owen makes it quite emphatic that nothing is being done at present and that there is no certainty of anything being done. The Del Norte Triplicate of Oct. 13, 1922, expresses the following sentiment with regard to the resignation of James H. Owen as head of the C. and O. Lumber Company: "J. H. Owen has resigned from the presidency of the California and Oregon Lumber Company, and has disposed of his interests in that concern, according to information reaching here this week, the resignation having already taken effect. "Mr. Owen built the town of Brookings and to his executive ability and farsightedness the concern reached a high pinnacle in the Pacific Coast lumber world. Hampered by every obstacle conceivable he kept his organization intact through the trying times of the war and soon as it was over he battled through the depression period, coming up with a bigger and better equipment to take care of the growing business. "Mr. Owen still has and represents large timber holdings in this county and contemplates entering business here, according to information reaching here. Mr. Owen's entry into the lumber business in Del Norte County would mean the construction and operation of another big redwood mill. The Triplicate feels perfectly safe in assuring him the full cooperation of the people in Del Norte for any payroll proposition he might inaugurate here." Medford Mail Tribune, March 8, 1923, page 1 M. D. OLDS BUYS BROWNLEE MILL

NORTH MEDFORD

The Brownlee Lumber Mill in Medford, with a capacity of 125,000 feet

every eight hours, has been sold to M. D. Olds, owner of the Pacific

& Eastern Railroad, and will be operated by Mr. Olds assisted

by

his son-in-law, G. L. Buhrman. Although the rumor of the sale has been

current for some time, it was only confirmed today. Neither party to

the sale would make public the consideration, but it is known to

involve a large sum. The transaction places the Olds interests in

control of a large supply of timber, transportation for the same, and a

mill to finish the raw product and will undoubtedly mean a great deal

to the commercial development of Medford and Jackson County.Mr. Olds is one of the largest timber operators in Michigan, and while very conservative and averse to publicity is known to be one of the most efficient and far-sighted operators in the country today. Since purchasing the P.&E. Railroad the Olds interests have spent hundreds of thousands of dollars in making improvements and extensions, and when completed this line will be one of the best logging railroads in the state. Mr. Brownlee has made no announcement concerning his future plans, but it is believed he will retain his interest in the timber development of Southern Oregon, and retain his residence in this city. Medford Mail Tribune, May 4, 1923, page 1 NOTE THREATENS BLOW UP PLANT

UNLESS MAN FIRED

M. D. Olds

of the Brownlee-Olds

Lumber Company received the following unsigned threatening letter

Friday morning:"Mr. Olds, "You better give a man with a family a job as night watchman. If you don't get rid of Grezier Shultz, the old pro-German, we will blow your planer to h--l." The letter is poorly printed on grey writing paper. About a year ago a letter of similar text and import was received by John R. Tomlin of the Tomlin Box Factory, and Newcomb's woodyard. Regarding the anonymous letter, M. D. Olds issued the following statement: "I wish to say to the writer of the above article that we have been employing all people that were willing to do a day's work, and wanted to work, and if the writer of the article has any grievance against Mr. Schultz, I would advise him to take it up direct with Mr. Schultz and not ask me to do things against Mr. Schultz that he would like to see done, and threaten the blowing up of my plant if I wouldn't do these things. "Brownlee-Olds

Lumber Co.,

County

authorities are investigating the letter."By M.D. Olds." Medford Mail Tribune, June 2, 1923, page 6 Night Watchman Replies

To the Editor: I would like to inform the party or parties that

were

cowardly enough to send Mr. Olds that letter in regard to myself that I

will be on duty at 6 p.m. on the night of the 5th inst., all being well, and that if they are bent on blowing up, to start with me, as it will not take as much dynamite to blow me up as it would to blow up the planer; and to be sure to make a good shot the first time, for if I have to shoot in self-defense I will strive to mark my man and protect the property left in my charge, and I hereby brand the writer of said letter a coward and a cur, with all the other foul names known in the English language. R.

R. SCHULTZ.

Medford, May 5."Communications," Medford Mail Tribune, June 5, 1923, page 4 BROWNLEE TO BUILD A MILL NEAR

MEDFORD

The lumber industry in Medford and Jackson County promises to be one of

the greatest resources in Southern Oregon, and the latest addition will

be the erection of another mill on the Rogue River, near McLeod bridge,

with a capacity of seven to eight million feet of lumber per hour.Work on New Structure at McLeod Started Today--New Planing Mill and Yard to Be Built in Medford in the Near Future. This will be erected by the Brownlee Lumber Co., that built the big mill in North Medford and recently sold the same to the Olds Lumber Co. Work on the logging camp near McLeod commenced today and the cutting of timber will be rushed, as will also the erection of the mill, which will begin next week. The machinery has all been ordered and will commence to arrive soon. The Brownlee Lumber Company will also put in a concentration yard and planing mill in Medford to handle the lumber from the McLeod mill. Work on the plant here will begin within 60 days. The company has established an office in the Medford building and the business and shipping will be transacted from here. Another mill of greater capacity will be commenced this fall by the same company at McLeod and they expect to run both mills the year round. They have 8000 acres of excellent pine and fir timber in that territory and the mills will both be located on their property. J. N. Brownlee has been in the lumber business for 43 years, came here a few years ago from Mississippi, purchased a big block of timber and erected the mill recently sold. R. O. Brownlee, his son, junior member of the firm, has also been in the lumber business several years. The people of Medford and Southern Oregon are glad the Brownlees have decided to remain here and erect these mills, as they are the kind of people that build up a community, and the new mills mean a greatly increased payroll for the city and valley. Medford Mail Tribune, June 28, 1923, page 1 MR. BROWNLEE MAKES STATEMENT

Referring

to your account of the council proceedings in last night's Mail Tribune,

there has evidently been a mistake as I have not asked for permission

to haul over the city streets. I have not decided where my plant will

be located and do not know that I will wish to haul over them.I made some inquiries from a city official as to the ordinances regarding hauling on the streets so that I could have the information in making my plans. Our city officials are as anxious as I am to build up Medford, and I am sure that should it be necessary to use the streets to establish a new enterprise such permission would be granted provided there is no danger of serious injury to the pavements. We all want Medford to have all the new enterprises we can get and we particularly need plants that can operate during the winter months. J.

N. BROWNLEE.

Medford

Mail Tribune, August 23, 1923,

page 3BROWNLEE MILL BOILER ROOM IS

GUTTED BY FIRE

A fire which started in the boiler room of the Brownlee-Olds Lumber

Company sawmill at the end of North Central at six o'clock last evening

damaged the boiler room to such an extent that the mill will be out of

operation for a month and completely destroyed the barn and burned one

horse to death. The financial loss has not been computed.Horse Burns to Death in Barn--Mill Out of Commission for Month--Foreman Gives Account of Start of Blaze--Traffic Congested at Scene. Sam Campbell, foreman, was just giving the night watchman final instructions and was making his inspection before leaving the mill for the night when he noticed a small spot of fire in the sawdust in front of the boilers. "I have put out such a spot many times with the water bucket," said Mr. Campbell this morning. "I walked over to it and stepped on it to smother it. In a flash the fine dust floating around in the air was ignited and exploded with a burst of flame, setting the whole boiler house on fire." By the time the hose was brought into action from the pumps outside the boiler house the fire had gained considerable headway, although the unkinking of hoses and the turning of the valves had taken but a minute or two. The mill employees battled the blaze for some time before the fire department was called. The department was called about 6:30 and arrived in quick time after the alarm had been turned in. Upon their arrival, the barn, a short distance southwest of the boiler house and in the direct line of the breeze that was blowing at the time, was burning fiercely. Six horses had been housed in the structure and five had been removed. The sixth was burned to death. Hoses were attached to the small water main which ends near the mill pond, but pressure was inadequate for effective fighting of the flames. Four lines of hose played weak streams on the fire from the small main and the flames were brought under control. The Forest Service fire patrol arrived with a gas engine pumping outfit, which was set to work pumping a fifth stream with an inch and a half line of hose from the mill pond, and rendered valuable assistance. The wind was in favor of the firefighters as it was blowing from the northeast and the flames of the burning boiler house were swept away from the mill and toward the horse barn. Several drums of lubricating oil and a drum of kerosene in the burning barn were cooled off and rolled away before they caught fire. The boilers were not damaged by the heat of the burning building to any serious extent. The stacks, however, were badly bent and twisted and several of them, that furnish the draft for the five large boilers, were damaged to an extent that will demand replacement before the mill can again be put into operation. According to G. L. Buhrman it is expected to be a month before the necessary repairs can be made. Mr. Buhrman would give no estimate on the damage done by the blaze but it is supposed that it will be found to reach several thousand dollars. The damage, however, is not as extensive as it was at first thought it would be, the boiler having remained practically undamaged. Hundreds of cars drove to the scene of the fire and spectators crowded the streets and blocked the traffic on the roads near the mill until it was necessary for officers to take the congested traffic in hand. In fact one arrest resulted from the refusal of a driver to comply with the request to move, made by a traffic officer. Medford Mail Tribune, September 1, 1923, page 1 OWEN COMPANY MAY CONSTRUCT

ANOTHER MILL

Papers were signed Friday afternoon whereby the timber holdings and

accessories of M. D. Olds were transferred to the Oregon-Owen Timber

Company, involving over a million dollars. It was the largest timber

deal ever consummated in Southern Oregon, and after the first

announcement of the sale several days were taken up in threshing out

details.The deal includes 11,000 across of timber in the Butte Falls district, where the Owen company has large holdings, the Pacific and Eastern Railway, 50 miles in length, the Brownlee-Olds sawmill of this city, and the camp and other equipment of Olds. Incidental to the above transaction is the purchase by the Owen company of 8000 acres of timber in the Butte Falls district belonging to J. D. Brownlee. "The completion of the Olds deal has somewhat altered our plans for the future," said James D. Owen, local manager and vice president of the Oregon-Owen company this morning. "A meeting of our directors will be held to consider plans for the construction of our plant in this city. There is nothing certain about what action they will take, but it is my guess that they will authorize its construction, as the Brownlee mill is too small to handle the volume of business that we want to handle. "Now that we have acquired the Olds properties, our first move will be to improve the railroad so it will stand heavy traffic, and finish the erection of a sawdust burner at the mill to eliminate the smoke nuisance and danger. "The magnitude of the deal we have just completed involves the picking up of a number of loose ends, and it will be some time before we get straightened out the way we want to be." Medford Mail Tribune, May 3, 1924, page 1 LOCATION OWEN-OREGON MILLS OF VITAL INTEREST

Shall

Medford possess a million-dollar lumber plant at the north end of town?

This is the question now being weighed in the mental balances of the

Owen-Oregon Lumber Company of which James H. Owen is vice-president and

general manager. It is his business sagacity and judgment which will

largely determine this most important matter, and a decision will be

reached in the near future, likely within ten days or two weeks. John

S. Owen, president of the company whose residence is Eau Claire,

Wisconsin, and other members of the firm have met here several times,

the last visit being last week, and it is definitely decided that such

a plant will be built in proximity to the company's large timber

holdings northeast of this city in the Butte Falls timber district.

This body of superb timber, consisting of billions of feet, is ripe and

ready for the saw, and the market is ready for it. The big plant to

transform the logs into lumber will be built, and the only question is,

where will it be located?TO MEDFORD BUSINESS Largest Industrial Plant in Southern Oregon Will Decide on Building Site Immediately. LOCATION OF MILLS IS TO BE DECIDED Advantages and Disadvantages

Considered

Medford has advantages. It is at the junction of the Southern Pacific

and the Pacific and Eastern railroads. The latter road is owned by the

Owen-Oregon Lumber Company and extends from here to Butte Falls and

into the company's timber lands. As a manufacturing site considered

from the point of shipping facilities, Medford has the edge on

other

locations. It is also a pleasant place to live, both for the management

and the help. Sufficient water can be arranged for both for steam and

the ponds and conditions generally are satisfactory. Barring three

important points it has advantages over the other contemplated sites.

The damp and foggy weather in the winter season requires dry kilns for

curing pine lumber, which blues easily.Places higher up--Butte Falls among them--will not require dry kilns. And the company has ample grounds at Butte Falls which it has not got here. It will require quite an addition to the present company holdings to supply room for this comprehensive plant. Another thing the management is considering: when a million dollars or more are placed in improvements alongside a city boundary, there is a great temptation to extend the limits and take in this source of revenue. City taxes added to state and county taxes as well as federal income taxes makes a heavy burden, especially for a new industry. But, as stated, a decision will soon be reached, for the head engineer is expected in a few days to pass on some technical points. Plant To Be Strictly Modern

All buildings, machinery and appliances will be strictly modern, and

the mill will cut seventy-five million feet of lumber per year,

according to manager James H. Owen. When the location is definitely

decided upon work will be immediately commenced and continue

methodically until the whole panorama of mills, ponds, buildings, etc.,

is completed. In addition to the million or more dollars invested in

the mill property, $200,000 will be spent in improving the railroad,

says Mr. Owen.The Brownlee-Olds mill taken over by the company has been remodeled and improved and is now running at full capacity, cutting 125,000 feet of lumber per shift. Many improvements have been added including a modern and expensive furnace for burning sawdust and waste from the mills. The employees are apparently well satisfied with conditions and have agreed to work nine hours per day, for which a minimum wage of 40 cents per hour is paid. Already three large concerns have secured concessions from Mr. Owen to build box factories near the new mills wherever located. Medford Clarion, July 25, 1924, page 1 OWEN-OREGON CO. GETS LOCOMOTIVE

The Owen-Oregon Lumber Co. have just received a large Willamette Shay

geared locomotive for their logging operation from the Willamette Iron

& Steel Works.They are also purchasing a heavy rod locomotive for their main line, so they will be in a position to haul thirty cars of logs per train as soon as they complete the retieing and ballasting of the main line. Medford Mail Tribune, August 15, 1924, page 12 OWEN OREGON CO. TO CONSTRUCT 5

BIG DRY KILNS

A force of 100 men are now ballasting and repairing the Pacific and

Eastern Railway between this city and Butte Falls, and immediate

construction of a battery of five dry kilns at their local plant are

two chief undertakings of the Owen-Oregon Lumber Company at present in

their Southern Oregon operations.The railroad will be put in first-class condition for winter operations, and the dry kilns will be rushed to completion. This addition will eliminate stains in lumber. The company recently purchased a new locomotive for logging operations and will use a fleet of high-powered caterpillar tractors with big wheels for hauling logs in the woods, instead of the stationary donkey engines. The tractors will be able to haul and handle 150,000 feet of logs a day. Manager James S. Owen of the local plant said Tuesday that the Owen-Oregon company would have a display at the county fair, in conjunction with the forestry service, showing the products of the forests. They will also show photographs of their equipment and the advances in transportation methods in lumbering, from the horse up to the giant mogul locomotive recently purchased. Medford Mail Tribune, August 20, 1924, page 2 OWEN-OREGON CO. STARTS TO BUILD

BIG WAREHOUSES

Work will be started at once by the Owen-Oregon Lumber Company at their

plant in this city on the construction of two lumber storage

warehouses, each 85 feet wide and 800 feet long. Each will hold

2,000,000 feet of finished lumber, and with a loading capacity of 20

box cars.The warehouse will be equipped with a crane, whereby the lumber will be handled, and will be stacked, sorted, and unstacked by machinery. The lumber will also be handled in packages containing about 2000 feet of lumber, an innovation in the business. Work will also be started at once on a battery of 15 dry kilns, each 105 feet long and 12 feet wide. The kilns will be connected with the storage sheds by automatic carriers and sorters. Plans for both these additions to the local plant were received Wednesday from Peter Swan, supervising mill architect of Portland. Manager Owen said Wednesday that as soon as the equipment could be secured, the local mill will be put on two shifts. The company has completed the ballasting of the railroad from the terminal in the timber to Butte Falls, and the crew is now working towards this city. The ballast is distributed at night, and new ties installed, and the tamping done in the daytime. When completed the railroad will be able to handle the heaviest traffic. It is expected that it will take from 60 to 90 days to complete the work. Medford Mail Tribune, September 4, 1924, page 3 BUILD OREGON-OREGON PLANT IN

MEDFORD

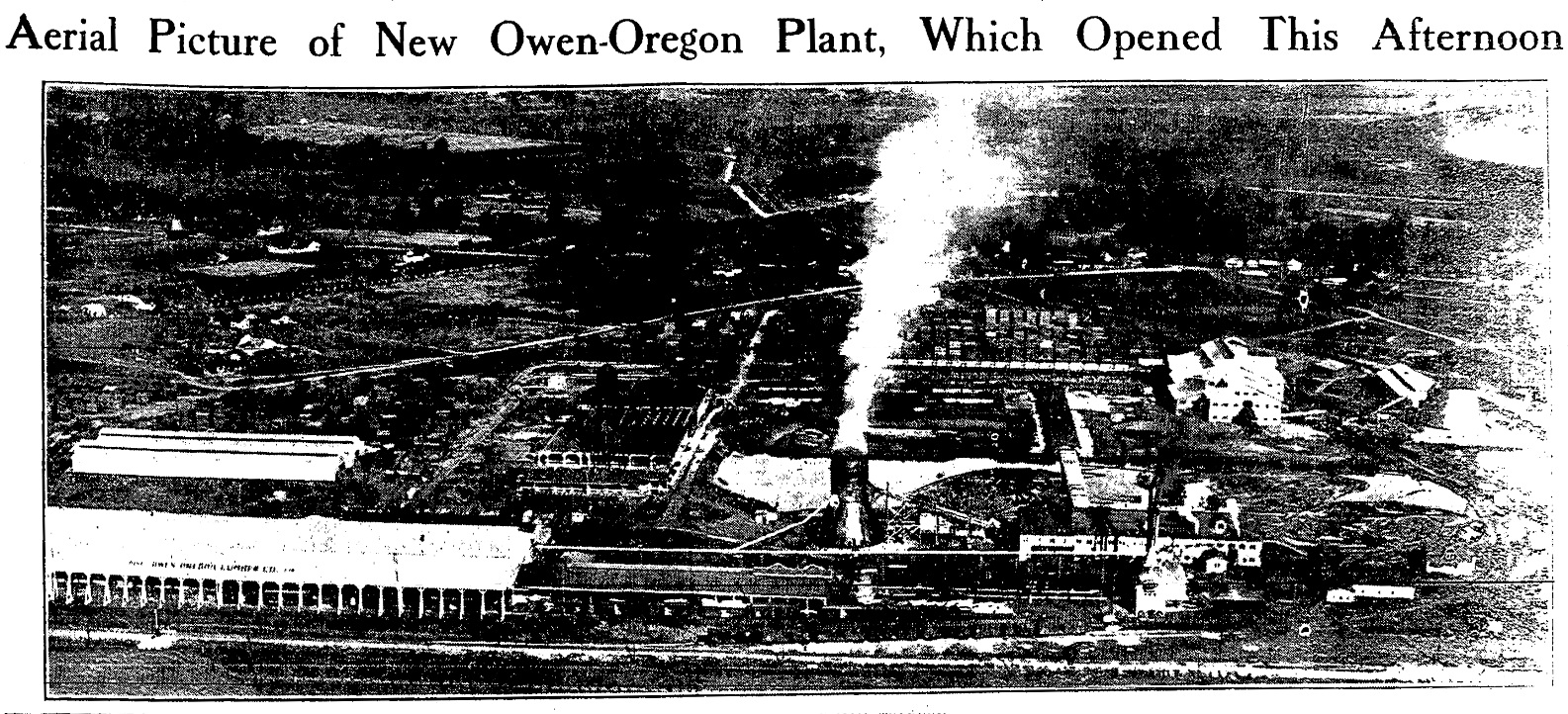

Definite announcement was made Tuesday that the main plant of the

Owen-Oregon Lumber Company would be built in this city by James H.

Owen, general manager of the company, on the present site near the

north end of Central Avenue, augmented by recently acquired property.

It is the most important and beneficial step in the industrial history

of Southern Oregon.MILL SITE DEFINITELY DECIDED ON James H. Owen, General Manager, Makes Announcement That Definite Decision Has Been Made--Will Rush Work on Construction to Cover 100 Acres of Land. The plant will cover 100 acres of land when completed, and will involve an expenditure of approximately $1,000,000. The main features of the new industry are: The enlargement of the millpond to cover ten acres for the storage of logs. The building of a new planing mill, with new machinery. The construction of the first unit of Crane dry storage sheds. The erection of a battery of 20 dry kilns, five now being under way. Work begun on lath mill at once with a capacity of 15,000 per day. The building of a railroad roundhouse, machine shop, oil storage tanks, loading decks, storage and supply sheds. The operation of two camps in the woods--one for fir, and one for pine. The maintenance and operation of the Pacific and Eastern Railroad between this city and Butte Falls. Plans have been drawn for all of the above work, and contracts have been, let, or soon will be, for all of the above construction at early date. The building of the man mill will be deferred until the subsidiary plants are finished, the present mill being used in furnishing material for the new work. Manager Owen said that the date of the completion of the new big mill was indefinite, but would be rushed as fast as possible. Cut 75 Million Feet a Year.

The plant, when complete, will cut between 60 and 75 million feet of

lumber a year. The payroll will average in the neighborhood of $70,000

per month, with between 500 and 600 men regularly employed. The present

capacity is approximately 30,000,000 board feet per year. The present

payroll is about $45,000 per month, with 325 men employed. One of the

difficulties besetting the new industry is sufficient housing

facilities for the employees. The management announces that wherever

feasible and possible they will employ men of families.It is the present plan to operate on a double shift basis, beginning January 1, 1925, increasing the capacity to 50,000,000 board feet. The main mill, storage sheds, lumber yards, planing mill and other incidentals will be located north of the present railroad tracks, and the roundhouse, railroad yards and oil storage tanks will be located south of the tracks. Complete Water System.

A complete water and drainage system will be installed at once,

including a 1000-gallon-per-minute fire pump, fed by eight- and

ten-inch mains. A 100-foot steel trestle will be erected, with a

100,000-gallon storage tank. The entire plant will be equipped with

automatic fire sprinklers which spray at a danger temperature and sound

alarms of fire.The plant will be driven by electric power, steam being used in the dry kilns. The alleyways of the lumber yards will be paved with cement, to permit fast handing of the lumber by carriers and pilers. The plant will be modern and complete in every respect, and fitted with the latest devices of the lumber industry, including lumber stackers and unstackers, carriers from mill to dry kilns, handling of lumber by crane and hydraulic carrier trucks. Every recognized safety device will be installed in the plant, which will rank with the leading mills of the Pacific Coast. In the woods, the company will operate two separate and complete camps, one for the handling of fir, and the other for the handling of pine. In the pine camp, Holt and Best power caterpillars with big wheels will be used in the handling of the logs, and in the fir camp, steam yarders will be used. The Company Holdings.

The holdings of the Owen-Oregon company consist of 50,000 acres in the

Butte Falls district, with a contract from the United States forestry

service for the cutting of 100,000,000 feet of pine timber.The railroad will entail the operation of four locomotives in hauling logging trains. 100 men are now engaged in re-ballasting, re-tieing and strengthening and building new trestles along the right of way. Among the educational features established recently by the Owen Oregon company in its present plant is the installing of a school for lumber graders, with lectures weekly by a grading expert. This school is now regularly attended by from 30 to 40 employees. Property Is Secured.

Property needed by the lumber company in the operation of the plant was

procured this week, after being in abeyance for several weeks, and was

immediately followed by a definite statement from General Manager Owen

that the plant would be established here.The output of the mill will be evenly divided between fir and pine. Practically all the pine will be shipped to the eastern market. Fir will be shipped as far east as Oho, for manufacturing purposes largely, and a large percentage of the fir will be sold in California and the eastern markets. The city of Medford will start work immediately on the construction of a road and sidewalk from the end of North Central to the mill. Medford Mail Tribune, September 17, 1924, page 1 TO BE AT MEDFORD

Definite

announcement was made Tuesday that the main plant of the Owen-Oregon

Lumber Company would be built in this city by James H. Owen, general

manager of the company, on the present site near the north end of

Central Avenue, augmented by recently acquired property. It is the most

important and beneficial step in the industrial history of southern

Oregon, according to The

Medford Mail Tribune.

The plant will cover 100 acres of land when completed, and will involve an expenditure of approximately $1,000,000. The main features of the new industry are: The enlargement of the millpond to cover ten acres, for the storage of logs. The building of a new planing mill, with new machinery. The construction of the first unit of Crane dry storage sheds. The erection of a battery of 20 dry kilns, five now being under way. Work begun on lath mill at once with a capacity of 15,000 per day. The building of a railroad roundhouse, machine shop, oil storage tanks, loading decks, storage and supply sheds. The operation of two camps in the woods--one for fir, and one for pine. The maintenance and operation of the Pacific and Eastern Railroad between this city and Butte Falls. Plans have been drawn for all of the above work, and contracts have been let, or soon will be, for all of the above construction at early date. The building of the main mill will be deferred until the subsidiary plants are finished, the present mill being used in furnishing material for the new work. Manager Owen said that the date of the completion of the new big mill was indefinite, but would be rushed as fast as possible. Cut 75 Million Feet a Year

The plant, when

complete, will cut between 60 and 75 million feet of lumber a year. The

payroll will average in the neighborhood of $70,000 per month, with

between 500 and 600 men regularly employed. The present capacity is

approximately 30,000,000 board feet per year. The present payroll is

about $15,000 per month, with 325 men employed. One of the difficulties

besetting the new industry is sufficient housing facilities for the

employees. The management announces that wherever feasible and possible

they will employ men of families.

It is the present plan to operate on a double shift basis, beginning January 1, 1926, increasing the capacity to 50,000,000 board feet. Ashland Daily Tidings, September

18, 1924, page 1

P. AND E. RAILROAD INCORPORATED

AS MEDFORD LOGGING

Through articles of incorporation filed at Salem last week, the Pacific

& Eastern Railway is now the Medford Logging Company

railroad, a

subsidiary concern of the Owen-Oregon Lumber Company, and owned and

operated by them. The incorporators are listed us A. E. Reames,

president; Charles Reames, vice president, and V. V. Plymale,

secretary. The amount of the capitalization is $2,000,000.The railroad, built originally by the Hill lines, runs between the local plant of the concern and Butte Falls, and in its day has furnished many a boom story of railroad development in these parts. At various times it has been the link of a transcontinental line from Chicago to the Pacific Ocean, and has fallen into the hands several times of the Union Pacific, the Great Northern, and the Burlington lines, seeking new territory and a route into San Francisco. Nothing ever came of these rumors, however. Last summer it was acquired from M. D. Olds by the Owen-Oregon company who immediately started reballasting and repairing the roadbed for heavy traffic. They will operate four locomotives and extensive railroad equipment. Medford Mail Tribune, September 29, 1924, page 3 OWEN-OREGON CO. TO OPEN UP NEXT

WEEK, DOUBLE SHIFT

Medford

Mail Tribune, January 12, 1925, page 3

The. Owen-Oregon Lumber Company will start operating its plant in this

city, on a double shift, beginning next week, furnishing additional

employment to between 100 and 150 men. Accumulation of orders, and a

government contract for cutting timber in the Butte Falls district, is

given as the reason for the additional shift. Later the plant will run

three shifts, according to the announced plans.

New machinery is being installed in the local mill, and the work is being rushed. Another shipment of machinery is due this week. The superstructure of the shed for the housing of the lumber crane is up and the first unit of a battery of dry kilns has been completed and [is] ready for operation. Enlargement of the logging pond and the erection of a water tower have been completed. In anticipation of the double shift operations, the logging camps of the company have been operating all winter and have thousands of feet of logs decked in the Butte Falls district, ready for hauling by the Medford logging railroad (nee P.&E.), a subsidiary corporation of the lumber company. The city has not yet fulfilled its promise to fix the road leading to mill property, and as a result the mud is hub deep, and rivaling the far-famed "fields of Flanders," causing great inconvenience alike to traffic and pedestrians. OWEN-OREGON CO. FIXES UP ROAD TO

LOCAL MILL

H. S. Lovejoy, of Janesville, Wis., secretary of the Owen

Lumber

Company, and A. R. Owen, of Owen, Wis., vice president of the concern,

will arrive tomorrow for a directors meeting of the Owen-Oregon Lumber

Company in this city. They are accompanied by John S. Owen, II, who has

been spending the holidays in Wisconsin. James H. Owen,

general manager

of the Owen-Oregon Company, leaves tonight for Portland to meet the

directors.The Owen-Oregon Company has started fixing the road to its plant. It is well nigh impassable, and gravel is being hauled on the thoroughfare to make the heavy hauling possible, as the mud is hub deep on a vehicle. Local officials agreed to macadamize the road, and to this end hauled sand and spread it, but the rain set in before it was finished. Medford Mail Tribune, January 14, 1925, page 8 OWEN-OREGON CO. WILL SOON SHIP 15

CARS PER DAY

Medford

Mail Tribune, January 29, 1925, page 3 The

annual spring rumor of railroad building in Southern Oregon has made

its appearance on the streets, and instead of heading for the Blue

Ledge mine, the former standby, the mythical line is being built in the

opposite direction. "Dame Rumor hath it" that the Medford Logging

Railroad (nee P.&E.) operated by the Owen-Oregon Lumber Company

will be extended to Bend, Oregon.

"We never dreamed of such a thing. Preposterous!" said James H. Owen, general manager of the Owen interests in this section, this morning. "That's the biggest pipe dream I've run across in a long time." The local plant of the Owen-Oregon Company is now operating on a double shift, and cutting approximately 240,000 feet of lumber a day. This output with the byproducts will average about 15 cars a day, to be shipped out of the valley. A. R. Owen, a director of the lumber concern, is making a general survey of the plant and timber holdings in this section, and considering future plans of the company, which have not been definitely decided upon. The Tomlin box factory Wednesday received ten new flat cars, which will be used in hauling logs over the Medford logging railroad. The flat cars were switched to the Tomlin plant this morning, and will be put in operation as soon as weather conditions permit. PAVEMENT WILL BE CONSTRUCTED TO

OWEN-ORE. MILL

Medford

Mail Tribune, February 4, 1925, page 3

At a meeting of the county court this morning, it was decided to

fulfill the promise made by the last county court, and pave the road to

the plant of the Owen-Oregon Lumber Company.

The county agreed to furnish $285, the city $200, and C. J. Semon agreed to build the road for $485, construction to start as soon as weather conditions permit. Owing to the rains and the heavy traffic this winter, the road is now in a deplorable shape. WORK IS STARTED ON NEW ROAD TO

OWEN-OREGON CO.

Medford

Mail Tribune, February 5, 1925, page 2

Work began today on the extension of North Central Avenue from the city

limits to the Owen-Oregon mill, by C. J. Semon, who was awarded the

contract Wednesday for the road building.

The road will be 16 feet wide and built of crushed rock, to cost $485, $285 being furnished by the county and $200 by the city. Semon guarantees that the road will stand up under any kind of traffic, in any kind of weather. A delegation of citizens called on the county court Wednesday morning in regard to the road, and got prompt action without argument. The city was represented by Mayor Alenderfer, the Chamber of Commerce by Robert H. Boyle, the business interests by Vernon H. Vawter of the Jackson County Bank, and Floyd Hart for the Tomlin box factory. OWEN-OREGON CO. HAS TIMBER TO

LAST 20 YEARS

Gain Robinson of the Owen-Oregon Lumber Company was the principal

speaker at the Kiwanis luncheon at the Hotel Medford yesterday, and in

his talk he told of the vast importance of the lumber industry to

Medford. Many facts regarding the operation of the Owen-Oregon Lumber

Company were brought out and inasmuch at facts were of interest to

every citizen of our community, some of them are quoted herein.Gain Robinson of Local Company Gives Interesting Facts Concerning Medford's New Industry--Fourth Largest Pine Mill on Coast. The Owen-Oregon Lumber Company has 50,000 acres of timber under its control, practically all located in the Butte Falls district. There are approximately a billion and a half feet of lumber in this acreage, sufficient to last for 25 years at the present rate of their mill production. The company is extending its operations into the "Four Bit" timber reserve and expects to start cutting this timber the coming summer. In addition to the present road to Butte Falls, 18 miles of logging road has been added and all of the track from Medford to the timber has been put in fine shape. It was necessary to do considerable work on the old road bed in order to hold up under the heavy tonnage which is now being hauled over this railroad. In the timber the company has two modern geared-type locomotives and these haul the logs to Derby where the trains are brought into Medford with the very latest type 75-ton Baldwin locomotive. Eighty of the latest type logging cars are owned by the company. It is the plan of the company to have its sawmill completely motorized, building its present steam plant exclusively for dry kilns. At the present time the plant is operated with two shifts and cutting 240,000 feet of lumber daily or 60,000,000 feet a year. A fact which perhaps is not realized by the people of Medford is that the Owen-Oregon lumber mill is the fourth largest mill on the Pacific Coast, cutting pine lumber. The only other mills which exceed its production are the ones at Weed, McCloud and Red River. Ten big carloads of finished lumber are turned out at the mill every day and shipped out of Medford; this does not include byproducts. In a short time the company will have in operation its new lath and picket mill which will turn out 24,000 laths each day. Five dry kilns have just been completed and construction has been started on even more which will give the plant a total of 22 dry kilns in operation by fall. The new planing mill has just been completed and is considered one of the most modern and best on the coast. The company uses an 80-foot electric crane which is used for loading purposes in the yards and directly into the cars. Four lumber carriers are used in the yards. The company is building a new yard in order to handle its increased production and this yard is being tiled and built for permanency. At the present time the company is employing slightly over 400 men and its annual payroll at the present time amounts to over $750,000, and as operations increase it is expected that the payroll will reach the million-dollar mark. Local expenditures in Medford during the past two months amount to over $40,000, and it is the policy of the company to favor local purchases wherever they can be purchased on an equal basis here. These purchases consist principally of food, supplies for camps, gasoline, oils, etc. From the above figures one can gain a fairly good idea of the vast benefit this new industry is to Medford and the Rogue River Valley. Dr. E. J. Miller of Nashville, Tennessee, also spoke at the luncheon and caused considerable mirth by telling a number of short stories. Medford Mail Tribune, February 24, 1925, page 66 LOGGING CAMP OF OWEN-OREGON CO.

IS PRAISED

Medford

Mail Tribune, April 28, 1925, page 3

The logging camp of the Owen-Oregon Lumber Co., located on Four-Bit

Creek, is one of the most modern and attractive camps in this region,

according to Geo. H. West, lumberman for the Forest Service, who is in

Medford on business today.

The cook house, store rooms and dining rooms have been mounted on five flat cars and located on a spur of the logging road. Sidewalks have been built connecting these buildings with the bunk houses, of which there are 20, each housing four men. The camp is equipped with running water and shower baths. All garbage and rubbish is disposed of in sanitary pits; the buildings are painted battleship gray and the whole camp presents a neat appearance. Logging operations on this unit are under the supervision of the Forest Service since the area is within the Crater National Forest. Only the mature trees are being cut on this tract, and the most modern methods of logging will be used, particular care being taken to do a minimum of damage to the young growth, thus assuring a future crop of timber. It is estimated that another crop of timber will be of marketable size on the tract in 80 years, and in the meantime the watershed will still be protected. The Owen-Oregon Co. is doing everything possible to reduce the fire hazard during the operation. The brush is piled and will be burned late in the fall when little or no damage will result to the young trees and remaining seed trees. The building of the Owen-Oregon Lumber Company's new mill is progressing rapidly. "Building Activities in Medford Greater Than for Many Years," Medford Sun, May 10, 1925, page C2 OWEN-OREGON CO. GETS EQUIPMENT

FOR WINTER WORK

Medford

Mail Tribune, August 3, 1925, page 3

Plans for the all-winter operation of the logging camps and

local plant

of the Owen-Oregon Company have been completed, with the ordering of

equipment for handling timber in snow. In the summer, the company uses

Caterpillar tractors and wheeled carriers. In the winter they will use

donkey engines and steam skids, and follow Wisconsin methods of

handling logs in deep snow. The operations of the company have just

completed five more dry kilns, making a total of 12, and have started

construction of a shed 80 by 220 feet for the storage of new dry rough

lumber.

Stanley R. Hodgeman of Spokane, Wash., an efficiency expert, arrived Sunday and will inspect the local plant and file a report on the manufacturing and operation thoroughness and any needed improvements to increase the same. James H. Owen, general manager of the local plant, will leave next week for Eau Claire, Wisconsin, to attend the annual directors meeting of the company. OWEN-OREGON TO ERECT A $50,000

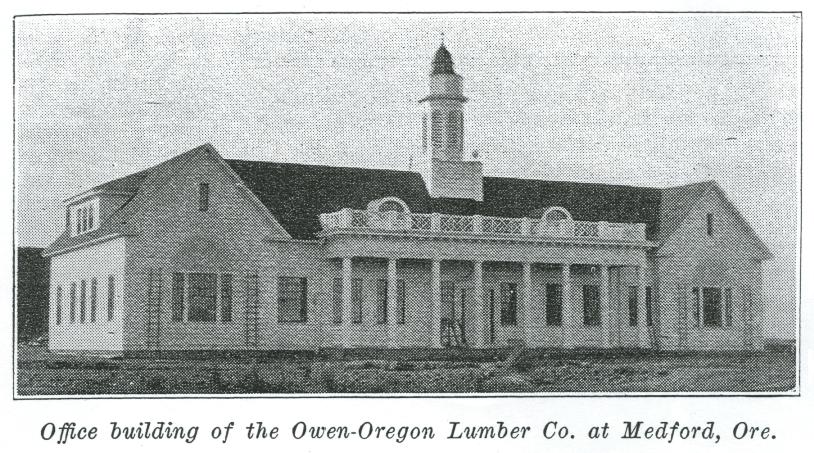

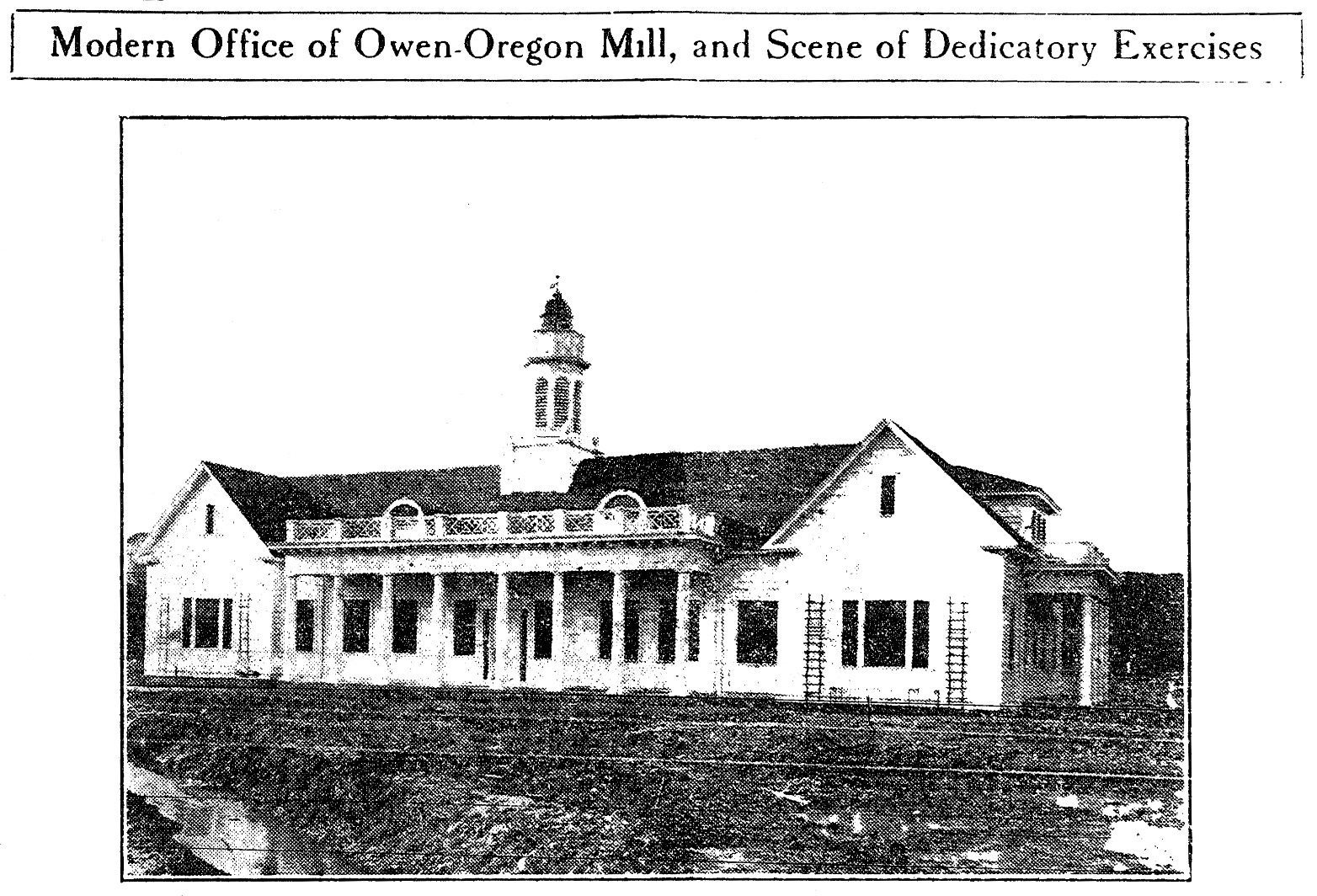

OFFICE BUILDING

Medford

Mail Tribune, October 28, 1925, page 5

Plans

are being considered by the Owen-Oregon Lumber Company for the

construction at an early date of a $50,000 office building, at their

plant in this city.

The building will be two-story, 100 by 75 in dimensions, and Gothic in design. It will provide quarters for every branch of the company's operations in Southern Oregon. The offices themselves will be the last word in equipment, with plate glass partitions, wickets, mahogany desks, and scientific lighting and ventilation systems. There will be a lawn around the building, with landscape decorations. The site for the building has not been selected, but will be on the mill property. The executive committee, of which John S. Owen of Oshkosh, Wis., is the head, is expected to meet early next month to approve and consider the plans made for a $500,000 improvement program of the local plant, operations on same to start in the spring. OWEN-OREGON CO. GIVES DINNER TO

100 EMPLOYEES

Medford

Mail Tribune, December 21, 1925, page 3

James

H. Owen, vice-president and general manager of the Owen-Oregon Lumber

Co., entertained about one hundred of the company employees at dinner

in the Craters' special dining room at the Hotel Medford last evening.

An exceptionally nice turkey dinner served under the direction of Emil

Mohr was greatly enjoyed by all present.

Unfortunately, the dining room facilities were not large enough to accommodate more than a hundred at one time, so it was not possible to invite the entire force of the company's employees for this occasion. More meetings of a similar type are planned for a little later on, in the hope that the men in the various departments of the operation may become better acquainted with each other. After dinner Mr. Owen outlined the company's contemplated improvements for the coming year, which included the drawing of plans for a new sawmill and office, with all the necessary smaller buildings and equipment to make the present operation new and complete from beginning to end. These plans will shortly be placed before the directors of the company for approval. All of those present were particularly interested in the company's plan to keep the mill in operation throughout the year, with shutdowns, as far as possible, confined to holidays. After hearing the outline of the proposed work for next year a number of the men were called on for suggestions as to improvements that might be made in present equipment, considered from a standpoint of increased efficiency and safety. Many good ideas were brought out along these lines and a number of quite helpful suggestions were made. It is hoped that at future meetings of this sort, the different employees will come prepared to offer any ideas they may have that will tend to increase the efficiency of the various departments, increase the output of the plant, and do away with unnecessary loss of time. It is probable that some sort of a social organization will be formed among the employees of the Owen-Oregon Lumber Co. that will be especially valuable to those families that are newcomers in Medford. It was generally agreed that the get-together evenings are extremely beneficial to all who are fortunate enough to be present, and it is hoped by the company that more of them can be arranged for in the near future. OWEN-OREGON COMPANY

WILL EXPAND

PLANS CALL FOR A HUGE INVESTMENT Nearly Million Dollars Involved in Building Program Approved by Executive Committee--$600,000 to Be Spent at Once--$300,000 for New Mill Held in Abeyance for Two Weeks.

A budget calling for the expenditure of approximately $900,000 for

improvements on their local plant has been approved by the executive

committee of the Owen-Oregon Lumber Company, according to an

announcement made this morning by general manager James H. Owen of this

city.

Of this amount, $300,000 is for the building of a modern, electrically equipped mill here, with a daily capacity, double shift, of 320,000 feet. This improvement is still in abeyance, and a final decision will be made within the next two weeks. Plans for the new mill have been drawn. The new mill construction provides for two band saws, 9- and 10-foot sizes, a gang and horizontal resaw--that is four main machines in addition to three trimmers. "There are several problems connected with the new mill," said Mr. Owen, "that require more time. In all events the capacity of the plant will be increased, if a decision is reached not to build the big mill. In case the new mill is not constructed, the present mill capacity will be increased, or a new small mill erected, in this city, or along the railroad line. If the new mill is built, it will be ready for operation by January 1, 1927." The expending of the remaining $600,000 in the budget is certain, and work on the improvements has been started, and will be carried on to completion as fast as conditions permit. The improvements, complete, are as follows: The installation of additional logging equipment. The purchase of a five-ton, 80-foot traveling crane, for handling lumber from the storage and shipping sheds. The building of a complete narrow-gauge yard rail transportation system, embracing 60,000 feet of trackage, several electrically driven locomotives, and 300 cars to facilitate the handling of lumber from the mill and planing department to the yard. Additional planing mill machinery to take care of the increased mill production. A new dry finishing shed, 100 by 200 feet in dimensions, for the handling of ceiling, moldings, and planing mill products that cannot be handled by cranes. Extension of the water and fire protection system. Construction of dry kiln sorting table and shed, for handling lumber from a battery of 15 dry kilns with mechanical unstackers and transfer from dry kilns to unstackers. Another dry lumber shed, 62 by 160 feet, for rough dry kiln lumber storage. Modern office building, complete throughout, to replace present quarters, the structure to be of architectural beauty and efficient accommodations, and furnished with modern office equipment. Erection of a 500,000-gallon steel oil tank, for the storage of fuel oil for locomotive and logging equipment. A new machine shop with hydraulic hammer and press, steam hammer, steel planer and other equipment. A fireproof roundhouse for the care and storage of locomotives and rail equipment. Enlarging mill pond to double present capacity for storing surplus logs and sorting logs. Fireproof fuel house for dry kiln batteries. Modern boiler house, with new high-power boilers, pumps and air compression. Supply warehouse for storage purposes of equipment. This is the largest program announced this year, for the state, and the largest in the industrial history of Southern Oregon. The executive committee, composed of John S. Owen, president and chairman, of Eau Claire, Wis.; H. S. Lovejoy, secretary, Janesville, Wis.; A. R. Owen, Owen, Wis.; Ben Alexander, Wausau, Wis.; George E. Foster, Wausau, Wis., and M. C. Woodward, Silverton, Ore. concluded their annual meeting in this city last week, and their approval of the improvement and building program was received before leaving, but announcement was with held. Medford Mail Tribune, January 19, 1926, page 1 PUT $500,000 INTO SAWMILL

Oregon Lumber Firm to Extend Plant at Medford.

MEDFORD,

Ore., Feb. 11. (AP)--The Owen-Oregon Lumber Company announced today

that it would start work within the next 10 days upon construction of a

new $500,000 sawmill in this city.

The new mill will be electrically operated, with a capacity of cutting 327,000 feet in a 16-hour shift. The new plant will be in operation by January 1, 1927. The increased capacity will mean the employment of 250 more men. The $500,000 sawmill is in addition to a $600,000 improvement of the present mill, now under way. Spokesman-Review, Spokane, February 12, 1926 FRED COLVIG, JR. WINNER IN O-O

ESSAY CONTEST

The essay contest sponsored by the Owen-Oregon Lumber Company during

Forest Week has been completed, and a number of commendable papers were

turned in by the pupils of the 7th and 8th grades, to whom the contest

was limited. The subject covered by these essays was "The Value of the

Lumber Industry to Jackson County," and the judges have decided that

the papers submitted by the following pupils are entitled to the prizes:

First prize--Frederick Colvig, Lincoln School. Second prize--Charles Green, Lincoln School. Third prize--Earl Carkin, of Roosevelt School. Fourth prize--Burton Lowry, Washington School. In accordance with the judges' decision checks in the following amounts have been given by the Owen-Oregon Lumber Co. to Mr. Hedrick, superintendent of city schools: 1st prize, $10.00; 2nd prize, $7.50; 3rd prize, $5.00 and 4th prize, $3.00. The judges of this contest, chosen by the directors of the Chamber of Commerce, were: E. H. Hedrick, A. J. Hanby and W. H. Crawford. The winning paper, written by Frederick Colvig, aged 12, son of Mr. and Mrs. Fred L. Colvig of 603 S. Riverside, is quoted in full below. Frederick won second prize in the Better Homes essay contest held in the schools last week. The Value of the Lumber Industry

to Jackson County.

Medford

Mail Tribune, May 6, 1926,

page 10

It is a well-known fact that the value of anything depends upon the

supply and demand. The smaller the supply the greater the demand, and

vice versa. Each year the amount of timber used in the manufacture of

lumber is being diminished and the value becoming greater.

Half a century ago the lumber manufacturers of the Middle West paid little heed to the value of conservation nor made any provisions for the future generation. With great waste the forests of Michigan and Wisconsin were stripped of their valuable timber, and the result is that today we see countless acres of cut-over lands which have been left valueless. This fact, and the growing scarcity of timber, has taught the lumbermen of today the value of conservation and reforestation. The fact that the forests have been exhausted in the Middle West led the large lumber operators to seek holdings in the Pacific Northwest, and now the manufacture of lumber represents one of the foremost industries of Oregon, where is to be found one-fifth of the standing timber in the United States. In Jackson County alone there is estimated to be twenty billion feet of standing timber, or one-fifteenth of all the standing timber in the United States. If this was manufactured into lumber it would provide material enough to build one million and a half six-room houses, allowing thirteen thousand feet for each house. The Owen-Oregon Lumber Co., the largest operator in Jackson County, employs 620 men and has an annual payroll of one million dollars. In 1924 they shipped 2745 carloads of lumber to all parts of the world. They have an investment in Jackson County of $6,000,000 in their plant, railroad and timber, and one can easily see what this means to our county, especially in the matter of taxation. The money which is paid out by this company for labor alone is of great value to every man, woman and child in the county, as it keeps money in circulation and helps the merchant. The mill affords steady employment for a number of people, which was not the case a few years ago when the only industries of any importance were fruit growing and agriculture. These industries offered employment for a short time only. Use Local

Trademarked O.-O. Lumber

Since July 1st this year the Owen-Oregon Lumber Company has been

trademarking all lumber shipped to the various lumber yards in Medford.

This O-O trademark will enable local people to identify Owen-Oregon

lumber if they wish to do so. The company decided to trademark their

lumber with the thought that there are a good many people locally who

believe in patronizing local industry, and who would insist on buying

lumber made in Medford if there was any way of distinguishing it from

stock shipped in from outside.If local lumber is used in all building here in Medford the Owen-Oregon Lumber Company will be able to keep up to capacity production, ensuring a continuance of a maximum payroll. Medford Mail Tribune, July 25, 1926, page 3 NEW OWEN MILL IN

OPERATION MARCH 1, 1927

Medford

Mail Tribune, October 18, 1926, page 1Delay in Arrival of Machinery Causes Change--Office on Highway, Nov. 1 Million-Dollar Building Program Nears Completion.

The new, modern, electrically equipped mill of the Owen-Oregon Lumber

Company will be in operation March 1, 1927, according to an

announcement made this morning by James H. Owen, general manager of the

company. It was originally intended to open the mill January 1, but

failure of machinery to arrive from the East changed the plans. The

mill is a part of the $1,500,000 building program of the company

inaugurated last spring.